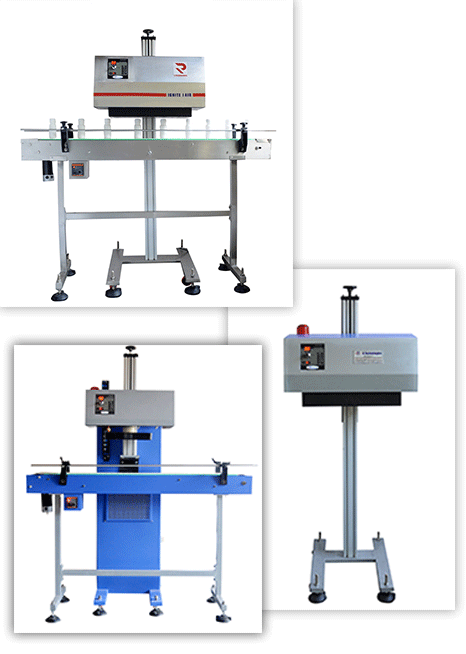

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer’s container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

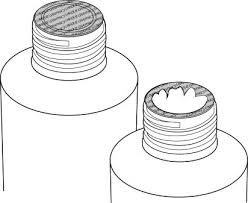

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product’s freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

This occurs when the original medicinal product is taken from its container and replaced with an ineffective or fake version. Unaware consumers are exposed to severe risks.

This occurs when the original medicinal product is taken from its container and replaced with an ineffective or fake version. Unaware consumers are exposed to severe risks.