Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

R Technologies sells induction cap sealers for any product or container to companies operating In India and worldwide.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

R Technologies sells induction cap sealers for any product or container to companies operating In India and worldwide.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

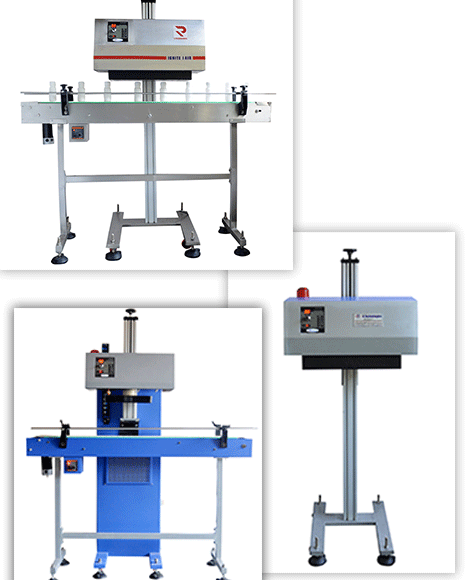

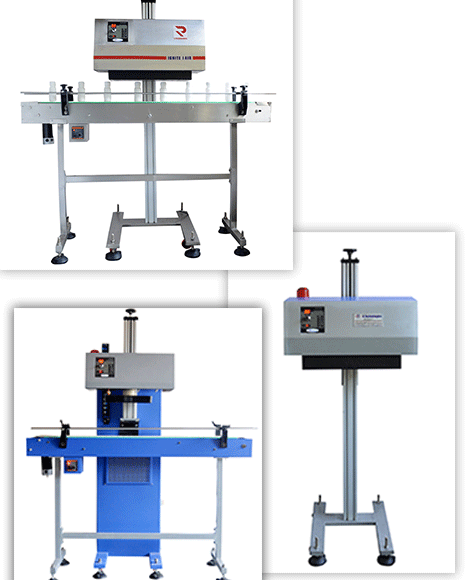

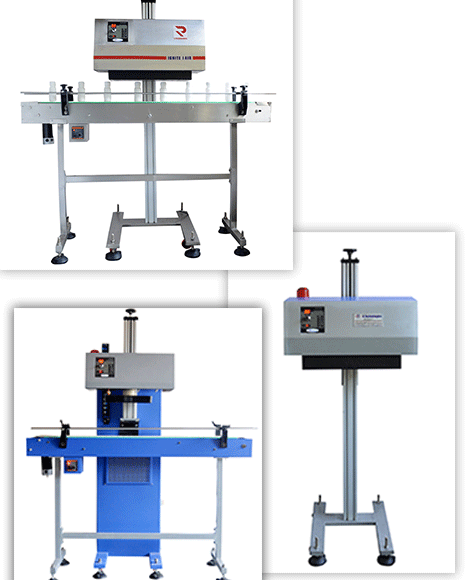

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

We have the most up-to-date induction technology machinery within our facilities at R Technologies. We use the best materials to produce quality barriers and operate in a fully equipped area known as a "clean room." We create personalized and one-of-a-kind designs.

We provide the coverings in a bag and box to assist their swift and secure transportation and subsequent storage. The packing procedure concludes at the customer's location. The client employs induction machinery during the production process to seal the operculum to the container previously put under the cap. The container is hermetically sealed after the procedure is completed. In this way, the product is marketed, keeping intact the properties of the contents of the package.

R Technologies is your dependable induction cap sealing partner.

We provide the coverings in a bag and box to assist their swift and secure transportation and subsequent storage. The packing procedure concludes at the customer's location. The client employs induction machinery during the production process to seal the operculum to the container previously put under the cap. The container is hermetically sealed after the procedure is completed. In this way, the product is marketed, keeping intact the properties of the contents of the package.

R Technologies is your dependable induction cap sealing partner.

This sturdy, flexible, and hermetic sealing method ensures the integrity of nutritional supplements, which are often offered as a powder.

Sport is becoming more popular, and it is normal to utilize nutritional supplements to improve performance. This is one of the industries that use induction sealing for its goods.

The majority of items sold are powdered, and no solution could ensure the product's quality after packaging and transportation. The induction sealing procedure allows containers to be firmly sealed and protected from:

As a consequence, the product is safe to consume and in perfect condition. Large sports nutrition firms, among others, employ induction sealing technology to ensure the quality of their products.

The induction sealing procedure is based on a metal disc (often tailored by each manufacturer) that seals the container's neck robustly, flexible, and hermetic manner.

Some advantages of the Induction Sealing procedure

Induction sealing is rapidly employed in various industries, particularly food and drinks, cosmetics, and chemicals.

Contact us regardless of your industry, and we will tell you of all the options for sealing your product or extra information in the operculum of your product!

Sport is becoming more popular, and it is normal to utilize nutritional supplements to improve performance. This is one of the industries that use induction sealing for its goods.

The majority of items sold are powdered, and no solution could ensure the product's quality after packaging and transportation. The induction sealing procedure allows containers to be firmly sealed and protected from:

- Leaks

- Oxidation

- Handling

As a consequence, the product is safe to consume and in perfect condition. Large sports nutrition firms, among others, employ induction sealing technology to ensure the quality of their products.

The induction sealing procedure is based on a metal disc (often tailored by each manufacturer) that seals the container's neck robustly, flexible, and hermetic manner.

Some advantages of the Induction Sealing procedure

- Because of its strong seal, it prevents leakage.

- Longer expiration: this technique stops the product from oxidizing.

- Manipulation of evidence: if the product has been opened, this can be easily demonstrated.

- Improve the brand's image: metal discs may be personalized with messages or emblems of the company.

Induction sealing is rapidly employed in various industries, particularly food and drinks, cosmetics, and chemicals.

Contact us regardless of your industry, and we will tell you of all the options for sealing your product or extra information in the operculum of your product!

The R Technology's induction cap sealing service lets you print your logo, discount coupons, promotions, instructions, or safety messages on the liners.

Working on your company's best visual identity is critical for your branding strategy to affect potential consumers and establish a compelling picture in the consumer's head. Even though the trend is becoming digital, conventional printed media should not be overlooked.

This is where Cap Sealing Products, R Technologies container induction sealing service comes in, allowing the corporate logo to be printed on the liner during the sealing process. As a result, when the customer removes the container seal and concentrates his gaze on the liner before finally opening the goods, it becomes a key communication point for the brand.

Furthermore, because induction sealing can be applied to many items, businesses from all industries may profit from this current brand image before the buyer samples the product.

Aside from the marketing above incentives, the following are some of the ways induction sealing in packaging may help to transmit messages to consumers:

Contact us regardless of your industrial sector, and we will inform you of all the options we have for printing your logo or extra information on the liner of your product.

Working on your company's best visual identity is critical for your branding strategy to affect potential consumers and establish a compelling picture in the consumer's head. Even though the trend is becoming digital, conventional printed media should not be overlooked.

This is where Cap Sealing Products, R Technologies container induction sealing service comes in, allowing the corporate logo to be printed on the liner during the sealing process. As a result, when the customer removes the container seal and concentrates his gaze on the liner before finally opening the goods, it becomes a key communication point for the brand.

Furthermore, because induction sealing can be applied to many items, businesses from all industries may profit from this current brand image before the buyer samples the product.

Aside from the marketing above incentives, the following are some of the ways induction sealing in packaging may help to transmit messages to consumers:

- Discount coupons: Assume you want to retain and reward your clients, so they continue to buy your items. One approach to accomplish this is to provide an extra discount on the container's liner so that only individuals who have previously purchased the goods may benefit from the deal.

- Recipes: Liners can feature recipes or sections of labels with the product's nutrient content, which is most common in the food industry.

- Games and quizzes

- Directions: The liner can offer information and instructions for removing it using a simple icon from the container.

- Promotional offers

- Safety Measures: Liners in cleaning products that are dangerous to children may have safety statements to inform customers.

Contact us regardless of your industrial sector, and we will inform you of all the options we have for printing your logo or extra information on the liner of your product.

Buy low-price, high-quality aluminium foil sealing machine with worldwide shipping with R Technologies. About of these are sealing machines, are other packaging machines. Aluminium Foil sealing machine is used to seal thermally plastic containers with aluminium foil. We offer Aluminium Foil Heat Sealing Machine to our clients.

Our Aluminium Foil Sealing machine is a manually operated machine. It is used for sealing the mouth of the different plastic products. Heat sealing of plastic plug done in. This portable machine works well with no place’s limits.

Suitable for aluminium foil, composite film sealing. Made of steel, designed for long - lasting use. R Technologies is top Manufacturer of Induction Cap Sealing Machines - Continuous Aluminium Foil Induction Sealer, Table Top Continuous Aluminium Foil Induction Sealer, Induction. R Technologies is prominent aluminium foil sealing machines manufacturers in India. For details about Aluminium Foil Sealing machines, visit our website for more info. Manufacturer of Foil Sealing Machine, Jar Sealing Machine, Aluminium foil cup sealing machine etc which are based at Mumbai.

The Aluminium Foil Sealer:

With R Technologies foil sealing machine, sealing a packet, a cup, a glass, or a package has become a simple process. This machine weighs around 15kg, is a hand-operated type that successfully seals boxes and prevents contents from flowing outside.

The machine can seal objects up to 100mm in diameter. It is powered by 230 volts. The principle of sealing machines is straightforward and beneficial. It helps apply a thin aluminium foil coating over the mouths of glasses, bottles, jars, and boxes. It keeps moisture from getting inside and causing damage to the contents. It also prevents the contents from leaking and spilling during distribution.

Because the foil sealer is manually controlled, the machine's speed is determined by the speed and efficiency of the person operating the equipment. R Technologies has been producing high-quality packaging goods and selling them to firms in various sectors since 2001. The company's goal is to assist businesses in lowering production costs without sacrificing product quality.

The Aluminium Foil Sealing Machine can be used in various industries, including pharmaceutical, textile, and automotive. Take advantage of R Technologies low-cost pricing. Call or check our website here at +91 22 27688599 to discuss our capping options and how they are suitable for your system.

Our Aluminium Foil Sealing machine is a manually operated machine. It is used for sealing the mouth of the different plastic products. Heat sealing of plastic plug done in. This portable machine works well with no place’s limits.

Suitable for aluminium foil, composite film sealing. Made of steel, designed for long - lasting use. R Technologies is top Manufacturer of Induction Cap Sealing Machines - Continuous Aluminium Foil Induction Sealer, Table Top Continuous Aluminium Foil Induction Sealer, Induction. R Technologies is prominent aluminium foil sealing machines manufacturers in India. For details about Aluminium Foil Sealing machines, visit our website for more info. Manufacturer of Foil Sealing Machine, Jar Sealing Machine, Aluminium foil cup sealing machine etc which are based at Mumbai.

The Aluminium Foil Sealer:

With R Technologies foil sealing machine, sealing a packet, a cup, a glass, or a package has become a simple process. This machine weighs around 15kg, is a hand-operated type that successfully seals boxes and prevents contents from flowing outside.

The machine can seal objects up to 100mm in diameter. It is powered by 230 volts. The principle of sealing machines is straightforward and beneficial. It helps apply a thin aluminium foil coating over the mouths of glasses, bottles, jars, and boxes. It keeps moisture from getting inside and causing damage to the contents. It also prevents the contents from leaking and spilling during distribution.

Because the foil sealer is manually controlled, the machine's speed is determined by the speed and efficiency of the person operating the equipment. R Technologies has been producing high-quality packaging goods and selling them to firms in various sectors since 2001. The company's goal is to assist businesses in lowering production costs without sacrificing product quality.

The Aluminium Foil Sealing Machine can be used in various industries, including pharmaceutical, textile, and automotive. Take advantage of R Technologies low-cost pricing. Call or check our website here at +91 22 27688599 to discuss our capping options and how they are suitable for your system.

While browsing the internet recently, I was astounded by the number of used induction sealers for sale on "used equipment" websites.

While a few of the systems were relatively new, the vast majority were either extremely old, outdated, obsolete, or overpriced! The majority of the equipment was sold "as is," with no warranty or guarantee that it would work at all.

I'm not saying that a good piece of packaging equipment can't be found at a reasonable price from a used equipment dealer. However, given the low cost of today's new induction sealing systems, why would a packager take a chance?

New semi-automatic systems can be purchased for around 2.5L. Automatic production line sealers are available for less than 6L each. New systems are guaranteed to function correctly and come with a full warranty.

In addition to the warranty, you will receive application assistance, readily available spare parts, and service support from an experienced staff. Used equipment dealers do not have the personnel or experience to provide this level of support.

So, if you're thinking about buying a used induction cap sealer machine, give us a call for a quote on a new system. You might be surprised at how cost-effective it is.

At the very least, contact us with information about the used equipment you're interested in, and we'll be happy to give you an honest appraisal and tell you whether it's a good deal or a dud!

While a few of the systems were relatively new, the vast majority were either extremely old, outdated, obsolete, or overpriced! The majority of the equipment was sold "as is," with no warranty or guarantee that it would work at all.

I'm not saying that a good piece of packaging equipment can't be found at a reasonable price from a used equipment dealer. However, given the low cost of today's new induction sealing systems, why would a packager take a chance?

New semi-automatic systems can be purchased for around 2.5L. Automatic production line sealers are available for less than 6L each. New systems are guaranteed to function correctly and come with a full warranty.

In addition to the warranty, you will receive application assistance, readily available spare parts, and service support from an experienced staff. Used equipment dealers do not have the personnel or experience to provide this level of support.

So, if you're thinking about buying a used induction cap sealer machine, give us a call for a quote on a new system. You might be surprised at how cost-effective it is.

At the very least, contact us with information about the used equipment you're interested in, and we'll be happy to give you an honest appraisal and tell you whether it's a good deal or a dud!

Induction sealing is a non-contact heating method that hermetically seals a container with a closure that incorporates a heat-sealable foil laminate within. When the proper seal is applied, the seal cannot be removed without leaving evidence on the container's lip.

In the 1980s, pharmaceutical firms began employing induction sealing to preserve their over-the-counter (OTC) medicines. The FSSAI accepts induction sealing as a reliable method of delivering tamper-evident packaging. Consumers increasingly demand a " safety-seal when they open a container containing pills, tablets, or liquid OTC medicines, consumers increasingly demand a "safety-seal."

Beyond safety, packagers have discovered that an induction seal has other benefits. The airtight seal works as a barrier, preserving the freshness of items such as oysters. Leaks are also avoided by using an induction seal, which may be found on various liquid items such as milk and oils.

For the reasons stated above, several food firms currently use induction seals. Many more people have recently contacted us to define a system solution for their application. For additional information on how a cap sealer works, please send us an email or call us at 022-27688599.

In the 1980s, pharmaceutical firms began employing induction sealing to preserve their over-the-counter (OTC) medicines. The FSSAI accepts induction sealing as a reliable method of delivering tamper-evident packaging. Consumers increasingly demand a " safety-seal when they open a container containing pills, tablets, or liquid OTC medicines, consumers increasingly demand a "safety-seal."

Beyond safety, packagers have discovered that an induction seal has other benefits. The airtight seal works as a barrier, preserving the freshness of items such as oysters. Leaks are also avoided by using an induction seal, which may be found on various liquid items such as milk and oils.

For the reasons stated above, several food firms currently use induction seals. Many more people have recently contacted us to define a system solution for their application. For additional information on how a cap sealer works, please send us an email or call us at 022-27688599.

Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

R Technologies sells induction cap sealers for any product or container to companies operating In India and worldwide.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

R Technologies sells induction cap sealers for any product or container to companies operating In India and worldwide.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

On the fifteenth anniversary of its founding, Cap Sealing Products -R Technologies- continues its adventure in the packaging sector, specializing in container closure using the induction sealing system. R Technologies has a large selection of induction liners.

R Technologies has been marketing induction sealing products for 15 years, including automated induction sealers, manual induction sealers, and consumables of various varieties and sizes for any product or container type.

15 years of experience providing services to the food, cosmetic, chemical, and pharmaceutical firms in India and Global. Working with SMEs to enhance safety and the quality of their products.

One of the secrets to the company's success is CSP's ability to modify and personalize the kind of induction sealing to each customer. This is only feasible because of my 15 years of expertise in this industry.

R Technologies retains the commercial flexibility with which it was born 15 years later, offering a wide range of materials for the sealing of any container, as well as a wide range of possibilities for customizing the product, either through dimension and form or individualized printings on the consumables.

Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.

Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers' evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

Proper Induction Sealing is met if:

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated - If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.

R Technologies offers materials for food enterprises that employ PET, PP, or PE and glass containers. Our Induction Cap Sealing Products also offers food package sealing services. As a result, we have the supplies necessary for food enterprises to profit from induction sealing.

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

Cap Sealing Products works with materials that are acceptable for food content in 90% of the cases. As a result, all of these materials meet Indian health regulations for items in contact with food.

Cap Sealing Products also provides products for food companies that employ PET, PP, or PE containers. We also offer material that is appropriate for businesses that package their products in glass containers.

Because the firm is aware that some of these materials include organic components, it has begun to advertise products with a ventilation system. Ventilation of the contents avoids container deformation in this sector.

Cap Sealing Products, goal is to provide induction liners that exactly match the closure mechanism comprised of the stopper and mouth of each customer's container in order to reap the benefits of induction sealing.

The most notable advantages of induction sealing in food products are:

- Tightness, which allows the packer to export the product without risk of leakage.

- Airtightness, which helps the product's freshness to be maintained.

- Evidence of non-opening, which provides the consumer with safety and high-quality guarantees.